MRT Control Unit

For automated control of MRT Spinning and Blasting Unit

The MRT Control Unit provides the opportunity, as control module for the preparation of sewer wall surfaces and coatings, for automised control of both processes.

Operation during substrate preparation and coating is carried out outside the manhole. Easy handling and rapid operation on site characterises the system. The casing and the control elements are robust and designed for practical operation.

By means of the remote control the entire process is automatically controlled by an integrated measurement system. The user has full control functions. The time saving compared to hand application is up to 80 %

more

Technical Data

| Supply data electric | 400 V 16 A |

| Dimensions controller (L x B x H ) | 26 cm x 55 cm x 70 cm |

| Dimensions remote control (L x W x H) | 33 cm x 8 cm x 13 cm |

| Weight Control Unit | 33 kg plus remote |

| Weight Chain hoist with 12 m Chain | 45 kg |

The MRT Control Unit consists of the following parts

- Switch cabinet

- Remote control

- Measurement System

- Chain hoist 250 kg (Abus) include 12 m chain

Optional

- Chain length up to 25 m

Technical Description

Hand operation

- Manual chain Hoist control via remote control (fast mode)

- Manual measuring of manhole depth with display readout

- Flexible selection of coating cycles with display readout

- Optical directional advice of stroke direction in the display

- Left and right handed rotation of the sling header

- Adjustable rotation speed (only Spinning Unit)

- Adjustable pneumatic centrilizer (Blasting Unit)

- Start rotation (Biasting Unit)

Automatic operation

- Autonomous moving of Spinning or Blasting Unit until individual specifications are achieved. (coverage, demolition ratio)

- Correction of coating cycle possible even during operation

- Manual change of rotation direction to avoid spinning shadows (Spinning Unit)

Download Technical Datasheet

HS Coating Head

The HS Coating Head is an separate feature for the Spinning Unit. Used for rehabilitation/ coating of manhole with ombran CPS or ombran FT.

more

Technicals:

- Only in combination with MRT Spinning Unit

- Made of stainless steel

- PM coupling for an easy adaption to Spinning Unit

- GeKa coupling for Material

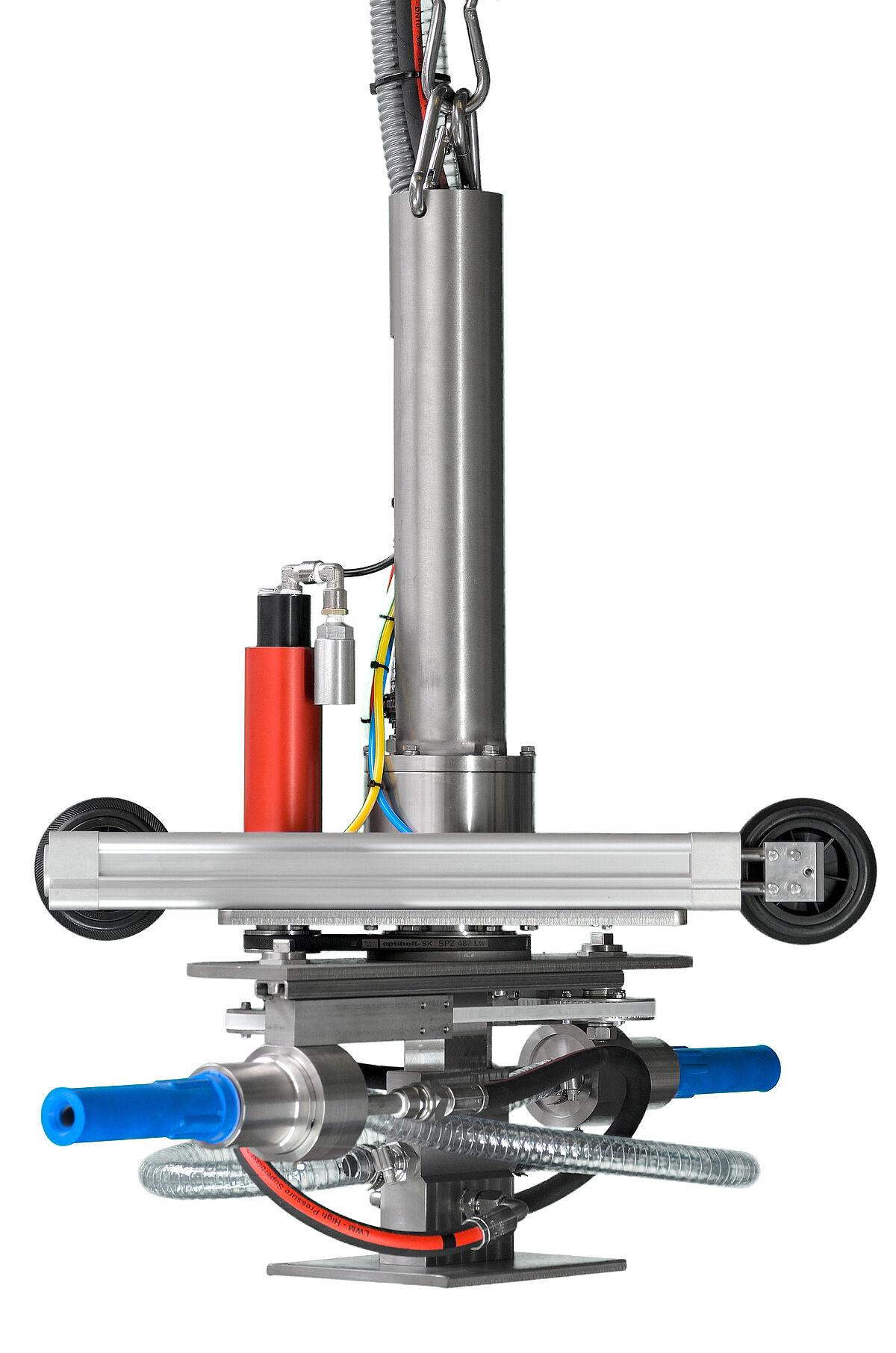

MRT Blasting Unit

Automated preparation of manhole surfaces

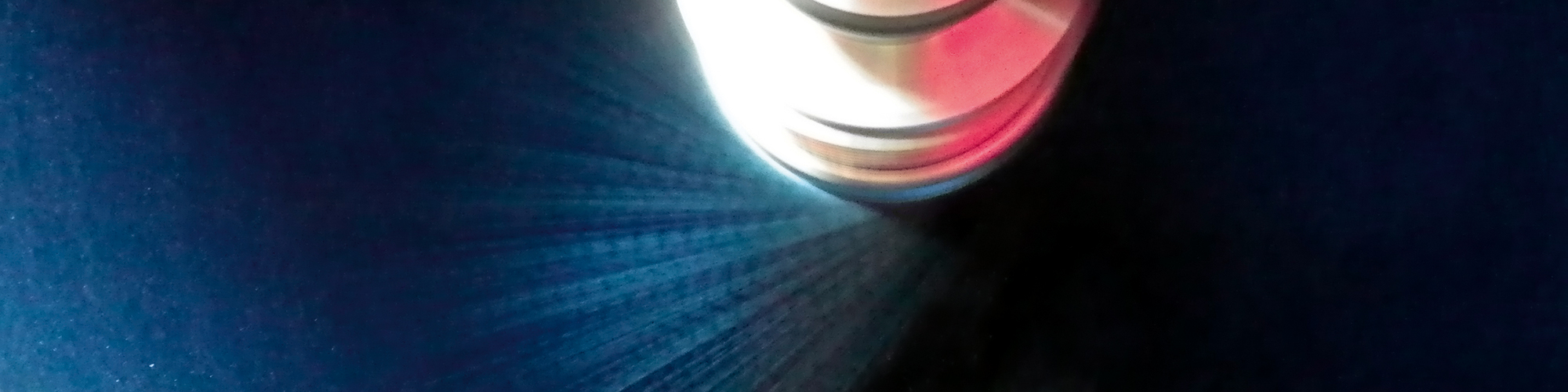

The MRT Blasting Unit is an automated controlable water/granules blasting unit for preparation of manhole surfaces in accordance with general regulations.

Due to parallel use of grit granules and max. 500 bar water pressure the required substrate preparation and demolition depth is efficiently achieved within a short time space.

ln combination with the MRT Control Unit the entire preparation is automated controlled by an integrated measurement system. The user has full control functions. Requirements concerning work safety are fulfilled.

more

Technical description

| Supply data water | hose connection M 22 x 1,5, up to 500 bar |

| Supply data air | Quick coupling / plug NG7, 4 – 8 bar 200 l/min |

Supply data electric | not required |

Nozzle size | adaptable to existing high-pressure water |

| Dimensions (L x W x H) | ca. 60 cm x 20 cm x 50 cm |

| Weight | ca. 30 kg |

| Granules tank size | moveable 60 ltr |

The Blasting Unit consists of the following parts

- 2 high pressure headers und diffuser

- Stainless steel made

- Pneumatic centralizer

- Pneumatic steering

- Synthetic granules tank, moveable

- Granules pipe 25 m length

Technical description

- Automated preparation of manhole wall surfaces

- Highly efficient due to use of grit granules and up to 500 bar water pressure (15 Ltr/min)

- Preparations of manhole wall surfaces in accordance with general regulations.

- Measurement system for controlled substance removal (in combination with Control Unit)

- Permanent Rotation of Blasting Unit – therefore homogeneaus preparation

- Operation outside the manhole

- Safety advantage due to automated operation without staff in the manhole

- Adjustable centrilizer position from outside with remote control

- Adjustable high pressure water headers from outside

Download Technical Datasheet

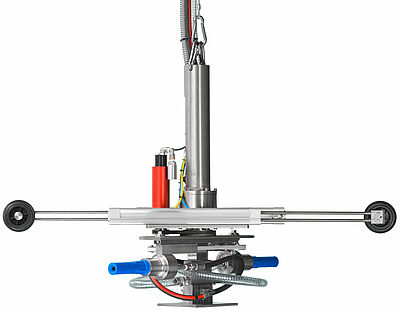

MRT Spinning Unit

Automated coating of manhole wall surfaces

The MRT Spinning Unit is an automated controllable sling header and therefore the operative unit of the system, used for rehabilitation/ coating of manholes with ombran MHP-SP.

The time saving compared to hand application is up to 80 %.

ln combination with the MRT Control unit the entire coating is automated controlled by an integrated measurement system. The user has full control functions.

Material duct, as weil as the sling header is made of stainless steel.

more

Technical data

| Supply data electric | 400 V 16 A / 1,5 KW |

| Rotation speed | up to 3940 Rpm (with control unit) |

| Weight | 34 kg |

| Dimensions (L x W x H) | 31 cm x 25 cm x 63 cm |

| Mortar supply | Putzmeister PM 35 mm |

The Spinning Unit consists of the following parts

- Electric motor 400V / 16A

- Made of Stainless steel

- Mortar supply: PM – coupling 35mm

- Sling header

Technical advantages

- Automated coating with ombran MHP-SP

- *measurement system for defined material application and increased safety

- *rotation speed regulation by adjustment to manhole diameter

- *left and right handed rotation to avoid sling shades (uncoated sections)

- operation outside the manhole

- low wear drive

- repeatable coating results

- especially adjusted to ombran MHP SP

- coating capacity approx. 1 sqare meter / 2,5 minute at 15 mm layer thickness

* only in combination with MRT Control Unit

Download Technical Datasheet