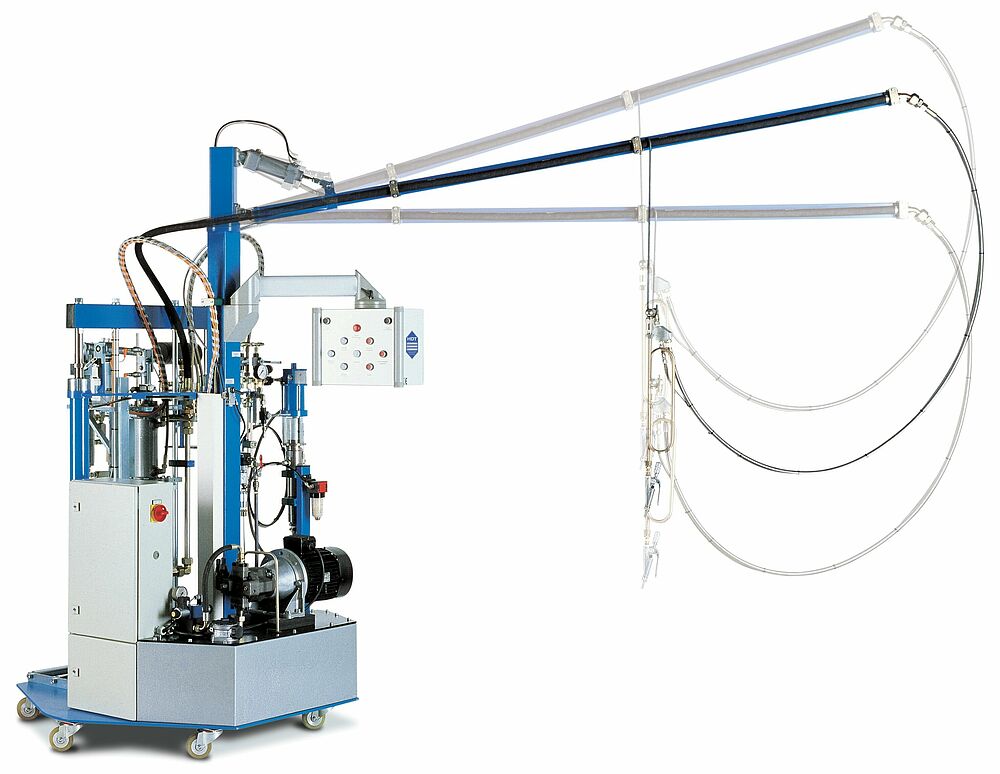

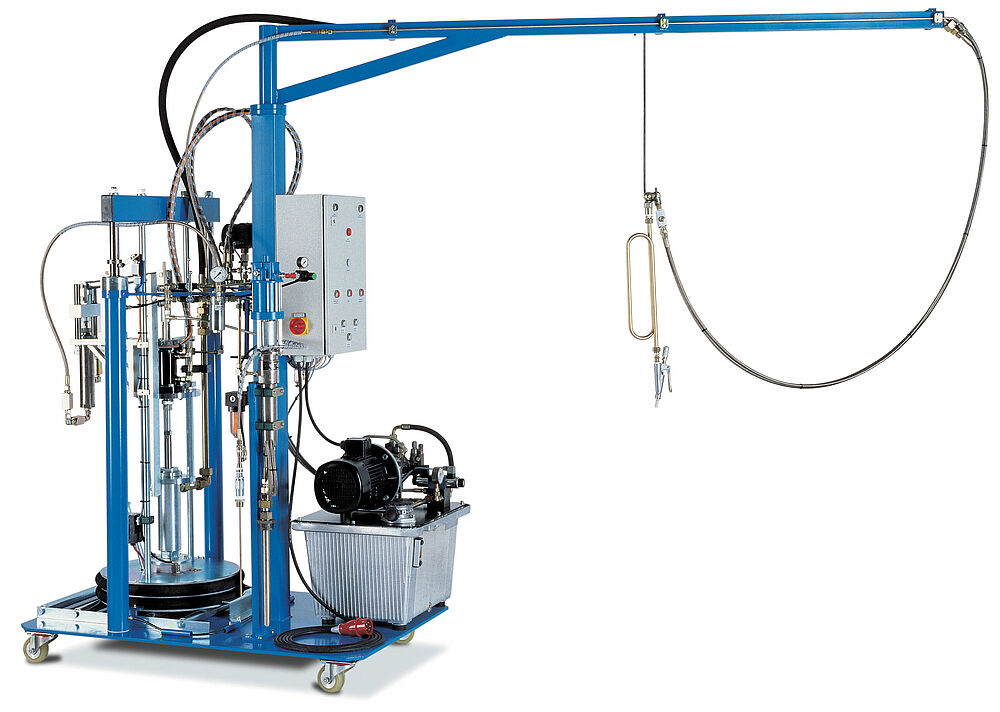

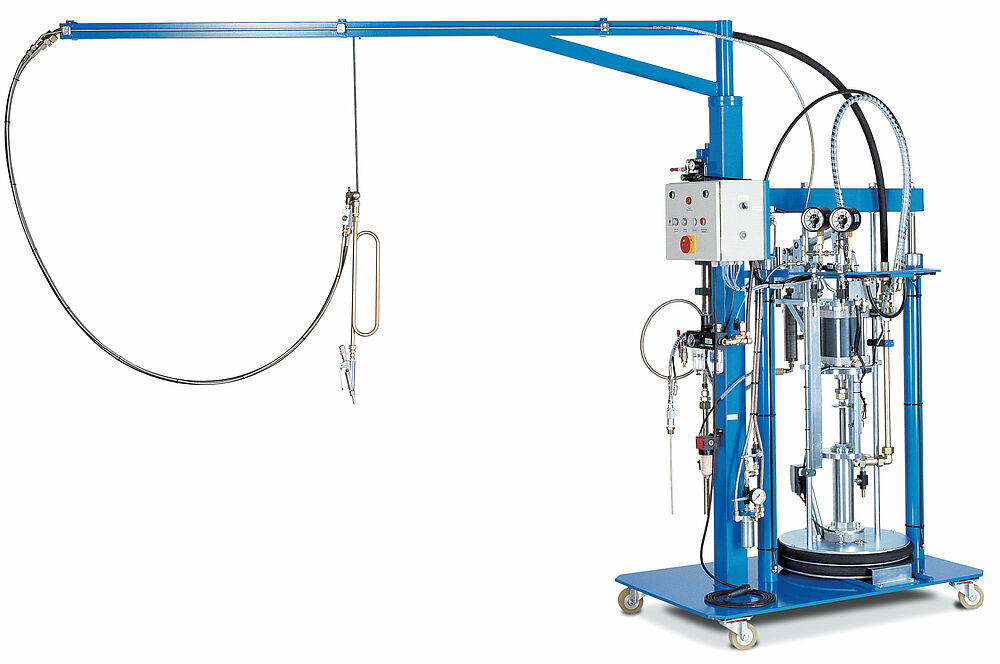

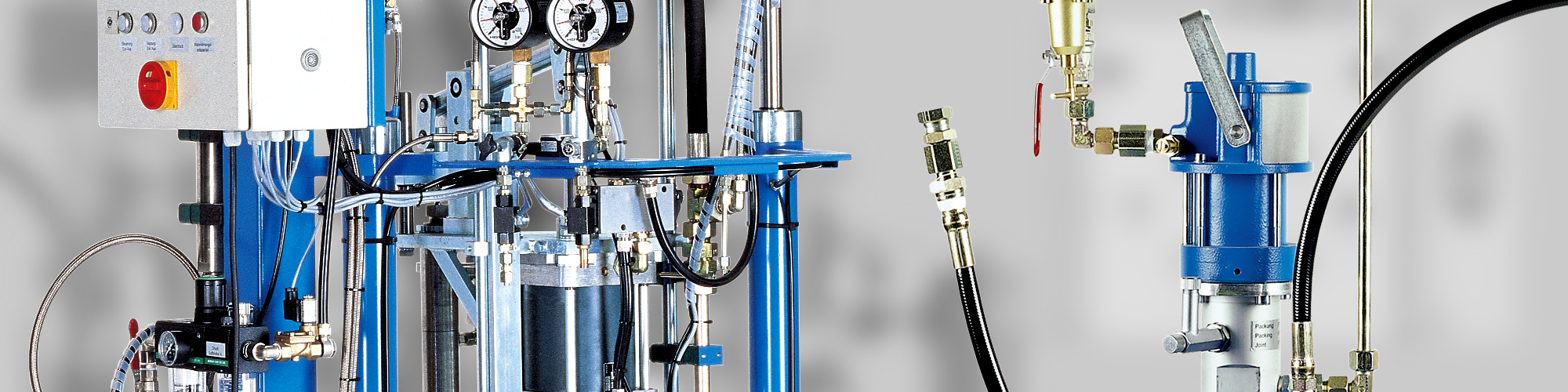

HD Pro-6 Easy

Save, Powerful and Ergonomic

The HDT Pro-6 Easy is the front-runner of the hydraulic HDT Hand Gunning Machines. Some of the eye-catching features are the new hexagon base plate which improves the stability and the moveable control panel. The pneumatically supported boom arm enables effective integration into the work process and optimum adoption to local conditions.

Technical Data

| Output | Approx. 5500 g/min (PU) |

| Electrics | 3 x 400V/N/PE 50Hz Fuse 16A, CEE Connection 16A |

| Pneumatics | 4 – 8 bar 3/8" |

| Measurements | Ø 1.240 x 2.400 mm |

| Weight | ca. 750 kg |

| Construction | mobile |

| Output control | Completely variable |

Standard Features

- Accuracy of new pump generation with long stroke results in highest maximum ratio

- Control Panel always visible

- Mobile Frame

- Variable mixing ratio

- Roller for ease of barrel change

- One hand mixing ratio control

- Two hand safety operation

- Heated follower plate (Base) (PU/ PS)

- Potlife control

- “Barrel empty” control

- Boom arm 2500 mm long with pneumatic support

- Automatic switch off at excess pressure or lack of material

- Follower plate designed for minimal rest quantity in barrel

- Complete mixing system

Accessories

- Purge Pump for solvent cleaning

- Freezer unit up to -45 °C

- Boom arm with customised length

- Boom arm heating system

- 200 litre hardener unit

- Special colour

- Feed Pipes with customised length

Download Technical Datasheet

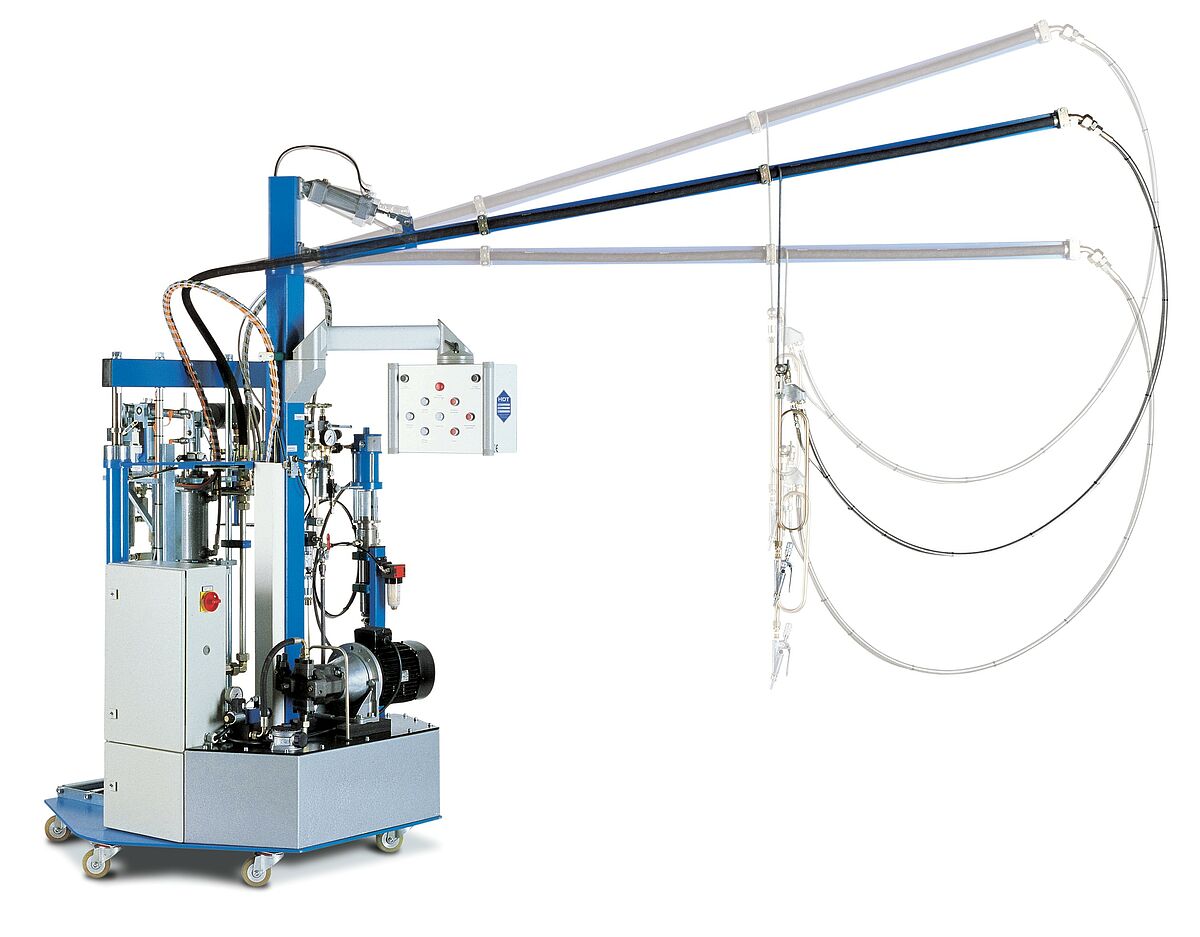

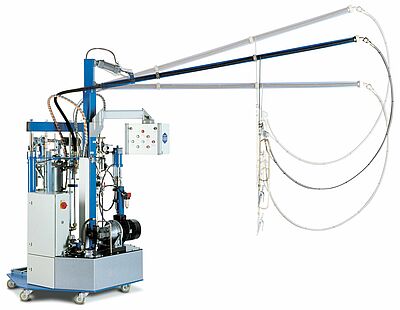

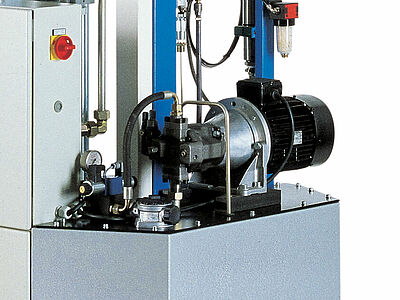

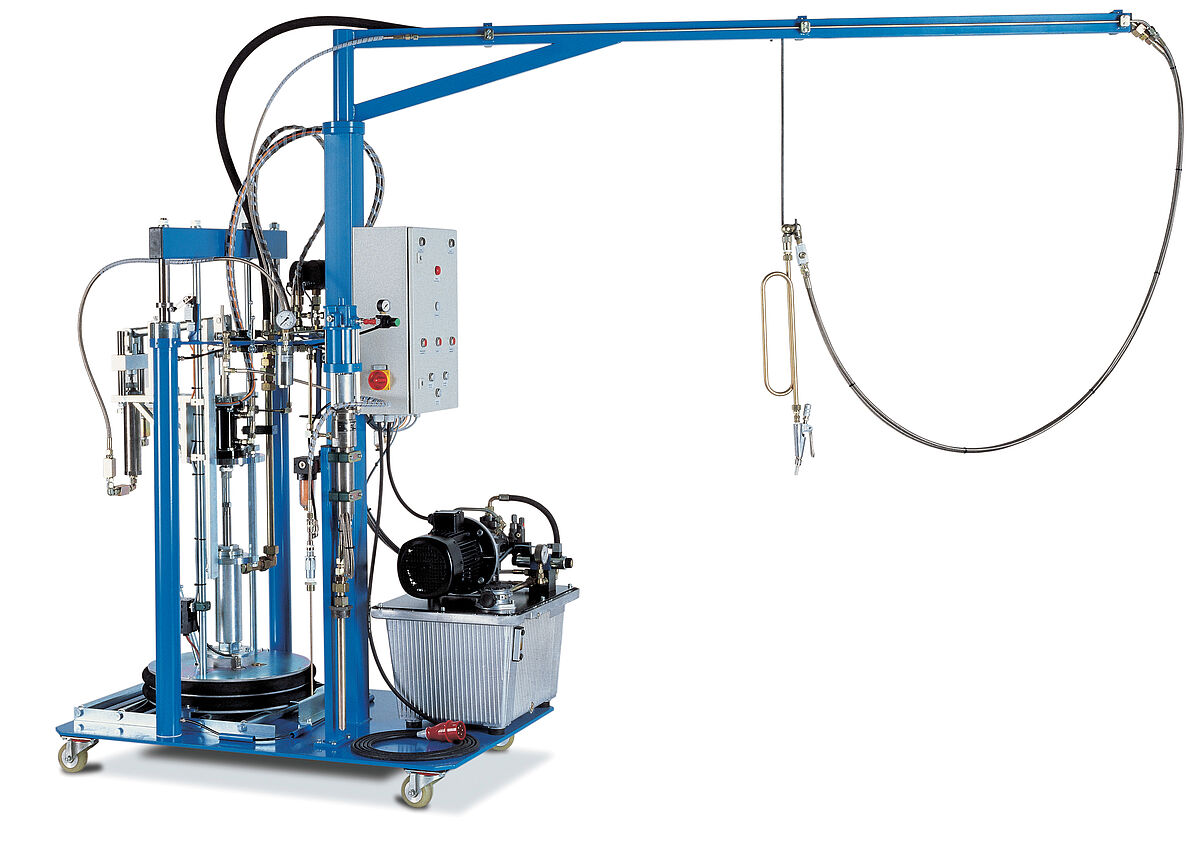

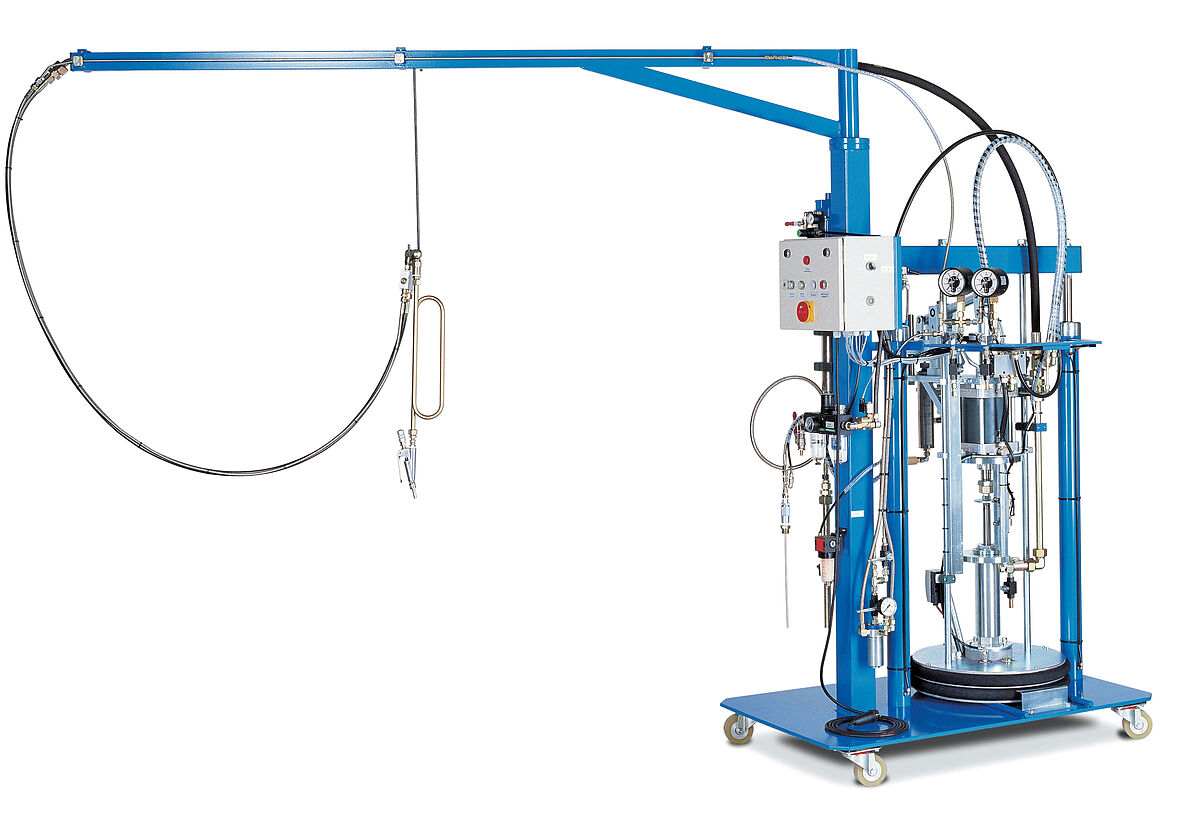

HD 200 Classic

Hydraulic and reliable proven technology

The HD 200 classic is a hydraulic hand-gunning machine, well proven in the market due to its high output, reliability and technical components.

The integration of many technical control systems guarantees the safety of theoperator as well as problem free production runs.

Consequently the standard features are the realisation of operators’ requirements. Use of our accessories enables further adoption to individual requirements.

more

Technical Data

| Output | Approx. 4.500 g/min (PU) |

| Electrics | 3 x 400V/N/PE, 50Hz, Fuse 16A CEE Connection 16A |

| Pneumatics | 4 – 8 bar 3/8" |

| Measurements | 1,4 x 0,95 x 2,4 m |

| Weight | Approx. 690 kg |

| Construction | mobile |

| Output control | Completely variable |

Standard Features

- Low maintenance pump technology

- Mobile Frame

- Variable mixing ratio

- Rollers for ease of barrel change

- One hand mixing ratio control

- Two hand safety operation

- Heated follower plate (Base) (PU/ PS)

- Potlife control

- “Barrel empty” control

- Boom arm 2500 mm long as standard

- Automatic switch off at excess pressure or lack of material

- Follower plate designed for minimal rest quantity in barrel

- Complete mixing system

Accessories

- Boom arm with pneumatic support

- Purge Pump for solvent cleaning

- Freezer up to -45 °C

- Boom arm with customised length

- Boom arm heating system

- 200 litre hardener unit

- Special colour

- Feed pipes with customised length

Download Technical Datasheet

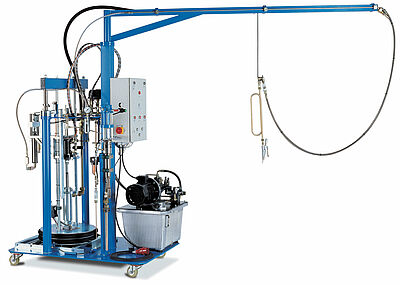

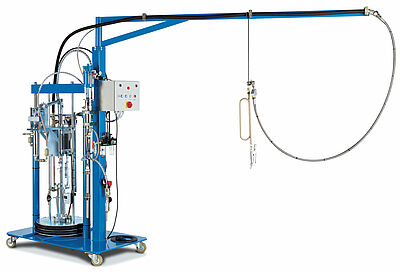

HD 200 Green Line

Hydraulic and reliable proven technology

Here it is the newest hydraulic machine from HDT GmbH, called HD 200 GL. The 2 component hydraulic machine saves energy through the new „Start – Stop“ function. The HD 200 GL automatically switches off when not in use.

Even in the basic version the advantages to the customer, such as safety processes and economical useage are available.

more

Technical Data

| Output | max. 2,5 kg / PU |

| Electric Connection | 400V / 16A / CEE |

| Pneumatic Connection | 4 – 8 bar 3/8" |

| Measurements )L x W x H ) | 1350 x 800 x 2400 mm |

| Weight | ca. 650 kg |

| Construction | fixed |

| Output Control | fixed |

Standard Features

- Hydraulic aggregate with 2,2 KW

- Maintenance free material pumps

- Automatic “Start - Stop” function

- Variable mixing ratio

- Automatic switch off at excess pressure or lack of material

- 2 hand safety operation

- 2 metre boom arm

- 2,5 metre hand held hoses

Addition

available for PS, PU or silicone

Download Technical Datasheet

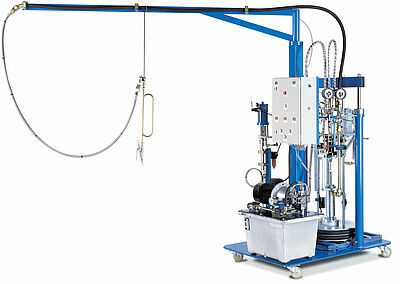

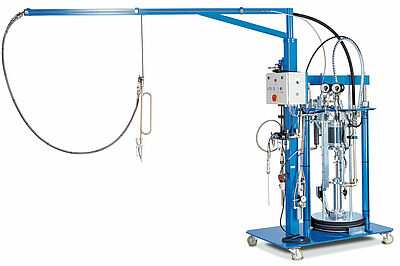

HD 200 Euro

Pneumatic –Quality in every Detail

The HD 200 Euro is a pneumatic hand gunning machine. It combines compact construction with ease of application due to intentionally not using complicated technology. Your advantage: Ease of operation and maintenance. The pumps are of the same proven quality as those used in the hydraulic versions.

Technical Data

| Output | Approx. 2.000 g/min (PU) |

| Electrics | 230V/50Hz, Fuse 16A, Safety Contact 16A |

| Pneumatics | 4 – 8 bar ½" Approx. 700L/min max. |

| Measurements | 1,35 x 0,8 x 2,4 m |

| Weight | Approx. 530 kg |

| Construction | mobile |

| Output control | completely variable |

Standard Features

- Low maintenance pump technology

- Mobile Frame

- Variable mixing ratio

- One Hand mixing ratio control

- Two hand safety operation

- Potlife control

- Boom arm 2500 mm long as standard

- Automatic switch off at excess pressure or lack of material

- Follower plate designed for minimal rest quantity in barrel

- Complete mixing system

- Maintenance friendly machine concept

Accessories

- Purge Pump for solvent cleaning

- Freezer up to -45 °C

- Boom arm with customised length

- Barrel heating system

- “Barrel empty” control

- Rollers for ease of barrel change

- Special colour

- Feed pipes with customised length

Download Technical Datasheet

HD F 32 / F 45

The HDT Freezer is equipped with very large cooling and heating tanks, particularly suitable for the fast freezing and thawing of the mixing units with mixed material. The reactivity of the materials is stopped in the cooling tank and subsequently it is reactivated in the heating tank.

This enables you to interrupt production at any time.

- HD F 32 for PU and PS

- HD F 45 for Silicon

Technical Data

| Contents: refrigeration and heating tank | 55 Litre each |

| Electrics | 230 Volt / 2,2KW |

| Temperature | refrig. tank -45 °C or -32 °C, heating tank +40 °C |

| Measurements | 71 x 72 x 125 cm |

| Weight | 160 kg |

| Construction | mobile |

Advantages

- No material loss

- Production without solvents

- No disposal problems

- Positive contribution to the protection of the environment

Download Technical Datasheet

HD Quick Clean (G)

The Cleaning System - effective and comfortable

Advantages

- Connection with Quick Couplers

- No mixer disassembly necessary

- handily and transportable

- simplest operation

- only air needed

- to use with HDT Ultra Clean

HDT Ultra Clean

- Intensive Cleaner on base of natural won Citrus

- In order to clean Mixers effectively

- To use in all usable Cleaning Systems

Download Technical Datasheet

HD 1K 20

1C – Pneumatic Hand Gunning Machine

For the processing and application of mono component adhesive sealants, pastes and greases of medium to high viscosity.

Technical Information

| Output | up to 1,5 kg/min. (depending on material consistency) |

| Output adjustment | variable |

| Drive system | pneumatic |

| Air Connection | variable 4 – 8 bar ½" Approx. 400L/min max |

| Construction | mobile |

| Dimensions (L x B x H) | 1350 x 800 x 2400 mm |

| Weight | 180 kg |

Advantages of this machine are

- 2 ram system, suitable for high viscous materials

- Adjustable high output

- Range of piping to suit different materials

- Special follower plate

- Boom arm 2500 mm long as standard

- Transport tube with Z-joint for optimum handling and flexibility

- Well proven sealing gun

Download Technical Datasheet

HD 1K 20 Compact

The HD 1K 20 Compact combines the proven technology and typical reliability of the HDT machines, while utilising a most compact design.

more

Technical Information

| Output | up to 1,5 kg/min. |

| Output adjustment | variable |

| Drive system | pneumatic |

| Air connection | 4 – 8 bar ½" Approx. 400L/min max |

| Hose lenght | 2.5 m |

| Construction | mobile |

| Dimensions (L x B x H) | 500 x 500 x 1.400 mm |

| Weight | appr. 90 kg |

Advantages of this machine are

- Due to design with twin lifting rams, machine is suitable for use with high viscosity materials

- High and variable output capacity

- Material compatible hoses and pipes

- Stability combined with Z-joint flexibility for optimal handling

- Proven sealing gun

Download Technical Datasheet